loads used in brinell hardness test|brinell hardness test pdf : fabrication What is a Brinell Hardness Test? Standards of Brinell Hardness Testing. Brinell Hardness Test Procedure. 1. Preparation of the Specimen. 2. Selection of Load and Indenter. 3. Test Machine Setup. 4. Load Application. 5. . WEBClique em “Enviar e-mail para o iFood”; Preencha os dados solicitados no formulário, nome, telefone e no campo “o que aconteceu”, informe que você quer excluir conta do .

{plog:ftitle_list}

Caldo de Pollo. Mely Martínez - México en mi Cocina. El caldo de pollo es una de esas comidas caseras que te hacen sentir bien; es alimento requerido cuando alguien está enfermo o simplemente necesita algo rico, nutritivo y con sabor a hogar. 4.79 from 70 votes.

In the standard method of the Brinell Hardness Test, we use 250 to 500 kg of load for soft material and 500 to 3000 kg of load for hard material such as steel and iron. In the standard method of the test, we use a ball indenter of .The Brinell test typically uses much heavier loads than the Vickers test, which could lead to discrepancies in conversion if the wrong load is assumed. To achieve accurate conversion, .Though loads of 500, 1000, 1500, 2000, 2500, and 3000 N are available in a typical Brinell hardness tester, a load of 500 N is used for testing relatively soft metals such as copper and .Though loads of 500, 1000, 1500, 2000, 2500, and 3000 N are available in a typical Brinell hardness tester, a load of 500 N is used for testing relatively soft metals such as copper and .

What is a Brinell Hardness Test? Standards of Brinell Hardness Testing. Brinell Hardness Test Procedure. 1. Preparation of the Specimen. 2. Selection of Load and Indenter. 3. Test Machine Setup. 4. Load Application. 5. .Though loads of 500, 1000, 1500, 2000, 2500, and 3000 N are available in a typical Brinell hardness tester, a load of 500 N is used for testing relatively soft metals such as copper and aluminium alloys, while the 3000 N load is often used for testing harder materials such as steels and cast irons. However, the general rule is that the .

The Brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. . Approximate loads and Brinell Hardness Numbers: Brinell Hardness Number vs. Load; Brinell Hardness Number Load (kg) 160 - 600: 3000: 80 - 300: 1500: 26 - 100: 500: With the Brinell hardness test, a carbide ball is pressed into the material. The indentation surface serves as a measure of the hardness! . Higher test loads are not the solution at this point, as this leads to deformation of the .

Portable Digital Refractometers fabrication

A chart is then used to convert the averaged diameter measurement to a Brinell hardness number. Test forces range from 500 to 3000 kgf. A Brinell hardness result measures the permanent width of indentation produced by a carbide indenter applied to a test specimen at a given load, for a given length of time.

The Brinell test also stands out due to its ability to apply higher loads compared to other hardness testing methods. This feature makes it particularly suitable for testing extremely hard materials that exhibit high resistance to indentation, such as hardened steels. . In the manufacturing industry, the Brinell Hardness Test is used to .When is the Brinell hardness test used? Brinell hardness testing is a commonly used method for determining the hardness of metals and alloys. The Brinell hardness test formula. When measuring hardness using the Brinell method, a hardened steel or carbide ball of known diameter under a known load is forced into the material being tested.The Brinell test typically uses much heavier loads than the Vickers test, which could lead to discrepancies in conversion if the wrong load is assumed. To achieve accurate conversion, make sure the loads used in the hardness test are consistent with those applied in standard conversion formulas.

A 10mm ball with an applied load of 3,000 kgf is most common for Brinell testing. Brinell tests are ideal for castings and forgings that may have rough surfaces or exhibit some chemical variation. Because the indentation ball is so much larger than in other testing methods, hardness values derived from the test provide a more representative .

Load: The Brinell hardness test uses a pre-load of 3 kgf, followed by the application of the main load, which ranges from 5 kgf to 3,000 kgf depending on the hardness of the material being tested. The load is applied for a set duration of time. . Additionally, Brinell hardness testing is used in the manufacturing of gears, bearings, and other .Other articles where Brinell hardness test is discussed: Johan August Brinell: .Swedish metallurgist who devised the Brinell hardness test, a rapid, . uses a 10-millimetre-diameter ball and a 3,000-kilogram load. Brinell hardness values correlate well with UTS. Much smaller loads and diamond microindenters also can be used in conjunction .The Brinell method is a static hardness testing method, which can be characterised as follows: It is one of the standardised procedures (ISO 6506, ASTM E10). The Brinell method has a test load range of 1 to 3000 kgf, which means that this method can be used for hardness testing in the low-load and, above all, macro ranges (conventional range).

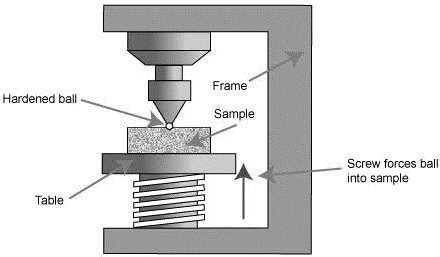

The Brinell hardness test. The Brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a tungsten carbide ball. . The term macro hardness testing is used when loads are higher than 1 kgf ; The Brinell hardness test measures material hardness by determining the diameter of an indentation made by a hardened steel or carbide ball under a specific load. A load, typically ranging from 500 to 3,000 kgf, is applied to the material’s surface for 10-15 seconds, allowing the ball to penetrate and create an indentation.This set of Testing of Materials Multiple Choice Questions & Answers (MCQs) focuses on “Brinell Hardness Test”. 1. What indenter is used for Brinell test? a) Hardened steel ball b) Diamond ball c) Diamond prism d) Steel prism View Answer. . Explanation: In Brinell test load is applied for a standard time. It is generally 30 second .

Brinell hardness test is one of the indentation hardness tests developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. . The Brinell .

Brinell hardness test is most commonly used to test materials that have a structure that is too rough or too coarse to be tested using other test methods, e.g., castings and forgings. In brinell testing machine the load is applied by a .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a .

In the Brinell hardness test, we use a small ball (the indentor) made of tungsten carbide or steel to penetrate the material's surface, leaving a hemispherical indent. From the load/pressure on the indentor and the diameter of the hole it makes on the material surface, we can calculate its Brinell hardness number. . From the load/pressure on .Applying loads of up to 3.000 kgf, the Brinell test is ideal for castings and forgings. . In the manufacturing industry, the Brinell Hardness Test is used to assess the hardness of raw materials, such as metals and alloys, before processing and fabrication. It helps manufacturers ensure that materials meet specified hardness requirements for .

The Brinell hardness test is a commonly used hardness testing method that measures the hardness of materials. It does so by pressing a hard ball indenter into the surface of the material under a specified load and calculating the hardness based on .The Brinell hardness number (HB) is the load divided by the surface area of the indentation. The diameter of the impression is measured with a microscope with a superimposed scale. The Brinell Hardness Number HB is computed from the equation: where P is the applied load of 3,000, 1,500, or 500kg. D is the diameter of the ball in mm. (10mm)

brinell hardness tester diagram

Due to the wide number of ball sizes and loads available, it is possible to test a very wide range of hardness values using the Brinell method. As the Brinell test uses relatively high loads, and therefore relatively large indent, it is frequently used to determine the hardness of the material which has undergone forgings or castings of large .Brinell hardness test is a method of measuring the hardness of metallic materials which is defined in the ASTM E10 standards. It is used to gauge the hardness and toughness of a material by measuring the depth of an indent left by an indenter on the test piece when it is compressed with a specified load.SCOPE. The Brinell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.How to use the Brinell hardness test for large samples with a coarse or inhomogeneous grain structure. Knoop Hardness testing (HK) . The required surface condition for the Vickers hardness test depends on the load used. Macro hardness testing (loads higher than 1 kgf) Surface should be ground; Micro hardness testing (loads below or equal to 1 .

Auto Abbe refractometer fabrication

Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. . The Brinell hardness number (HB) is the load divided by the surface area of the indentation. The diameter of the .

Each Rockwell hardness scale is identified by a letter designation indicative of the indenter type and the major and minor loads used for the test. The Rockwell hardness number is expressed as a combination of the measured numerical hardness value and the scale letter preceded by the letters, HR. There are a variety of hardness test methods in .

brinell hardness test theory

brinell hardness test pdf

Alina Becker - TW Pornstars - Top pornstar videos and pics

loads used in brinell hardness test|brinell hardness test pdf